Структура производства

Производственные подразделения:

Цех №1, по производству:

• носителей для катализаторов риформинга, изомеризации, гидрирования, гидроочистки;

• адсорбентов и осушителей.

Здесь закладывается основа пористой структуры готового продукта. Автоматизация технологических линий позволяет контролировать параметры процесса и регулировать структурные характеристики носителей и адсорбентов.

• носителей для катализаторов риформинга, изомеризации, гидрирования, гидроочистки;

• адсорбентов и осушителей.

Здесь закладывается основа пористой структуры готового продукта. Автоматизация технологических линий позволяет контролировать параметры процесса и регулировать структурные характеристики носителей и адсорбентов.

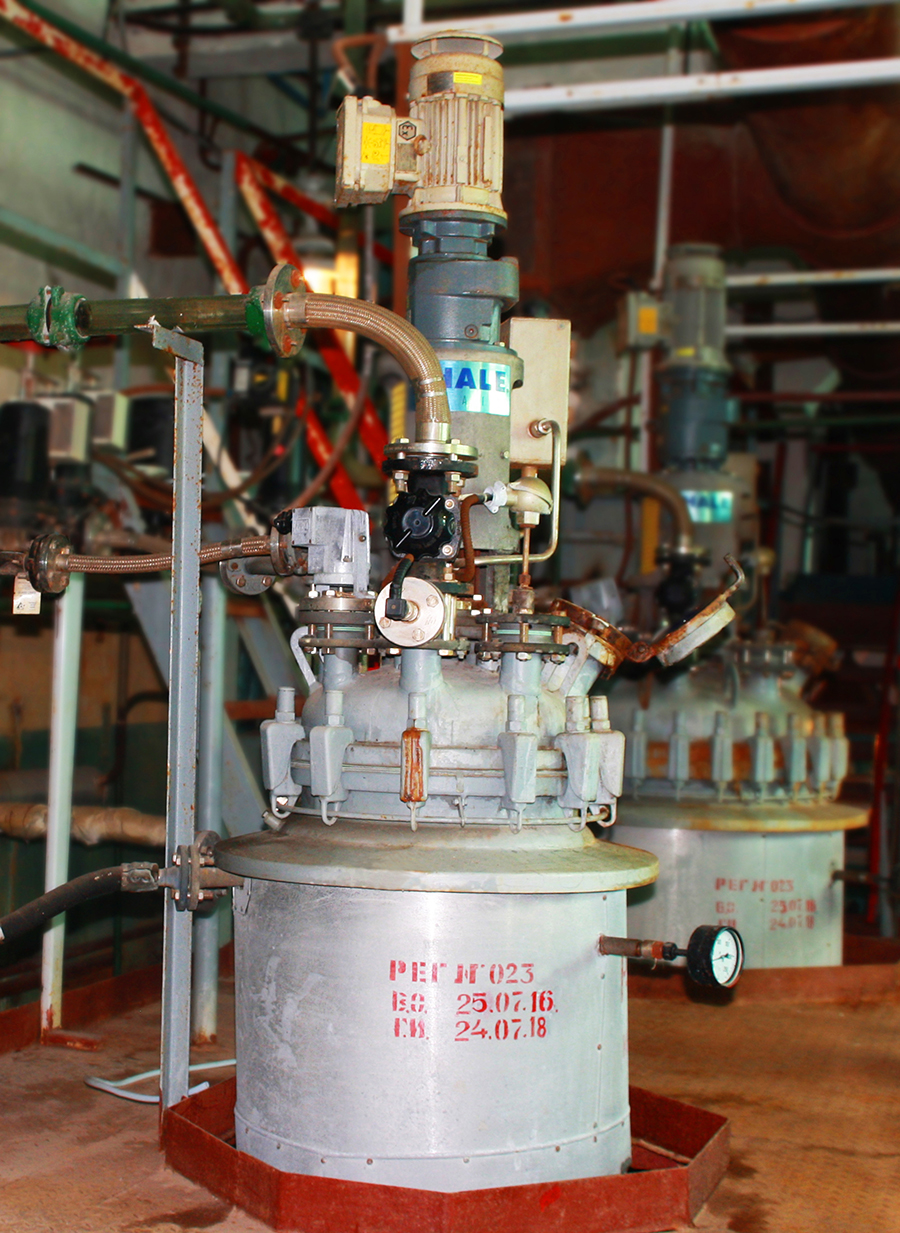

Цех №2, по производству:

• катализаторов гидроочистки;

• катализаторов Клауса;

• экологических катализаторов;

• осушителей;

• адсорбентов.

• катализаторов гидроочистки;

• катализаторов Клауса;

• экологических катализаторов;

• осушителей;

• адсорбентов.

Цех №3, по производству:

• катализаторов риформинга;

•

катализаторов изомеризации;

• катализаторов гидрирования;

• катализаторов гидроочистки.

Оригинальные технологии, современное оборудование и постоянный контроль являются залогом получения высококачественной продукции.

Вспомогательные подразделения.

Аналитическая лаборатория позволяет осуществлять широкий спектр работ по анализу, испытаниям катализаторов, адсорбентов, осушителей.

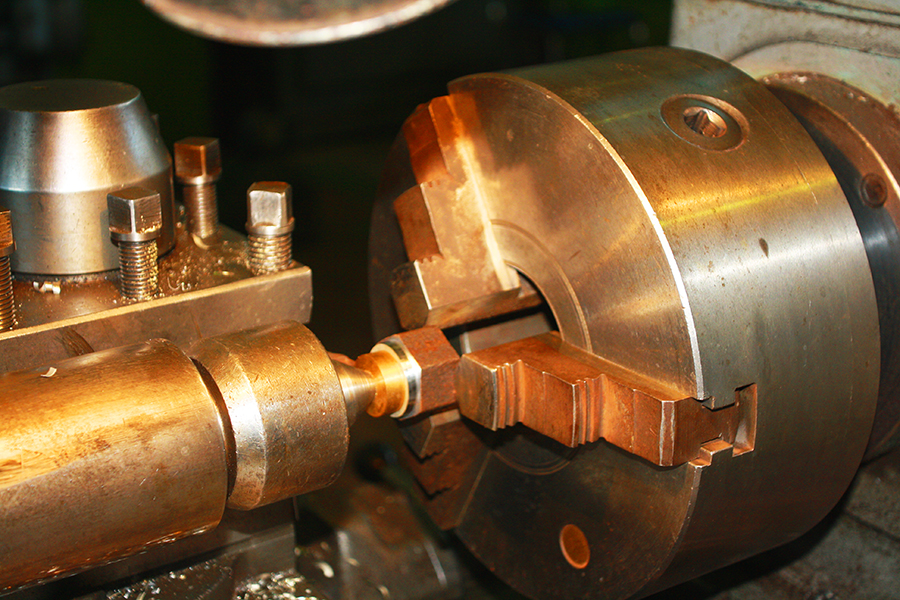

Наличие собственной ремонтно-механической, электротехнической и КИП служб, позволяет обеспечивать бесперебойную работу основных производственных подразделений.